-40%

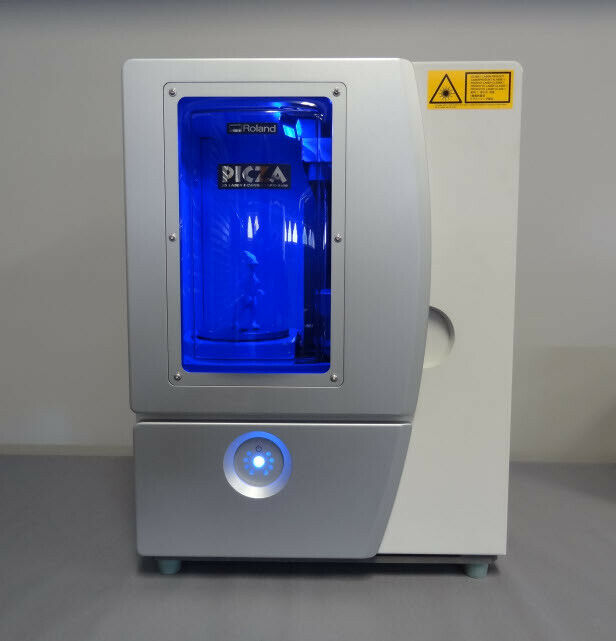

Roland LPX-1200 Automated 3D Laser Scanner

$ 2637.36

- Description

- Size Guide

Description

Roland LPX-1200 3D Laser Scanner with Upgraded Pixform Pro Software and ComputerSale Price 95 for everything

LPX-1200 Retail ,995

Pixform Pro Retail ,995

This LPX-1200 was used in a dealer showroom for display purposes. It was only used for a few demonstrations. It ships complete with all software and accessories just like a new system and we are including a computer that has everything setup. You can take this out of the box and start scanning.

We will not ship outside the USA.

Our company Product Development Inc is found on the web at PDI3D. Under our used equipment page there is a brochure you can download there. We have been selling and supporting the Roland equipment since 2001.

MESSAGE US FOR MORE PICTURES OF 3D SCANS IF NEEDED

INCLUDES

LPX-1200 Roland's Highest Resolution 3D Laser Scanner

4 Axis Scanning for Fully Automated 3D Scanning

Dr Picza 3 3D Scanning Software (all updates)

PixForm Pro Reverse Engineering Software (all updates)

Computer

Users Manuals

Free Online Training and Support

Onsite Training Available Anywhere (for an additional fee)

Ready to Ship - Ship to USA Address Only

Contact for shipping price, pickup is free

Ships on a pallet - Freight - I would approximate 0 East Coast and 0 West Coast.

Pallet size 32"x32"x36" shipping weight around 150lbs

We ship freight because small package is not handled as carefully.

The LPX-1200, Dr Picza 3 and Pixform Pro software are a perfect combination for 3d scanning and reverse engineering.

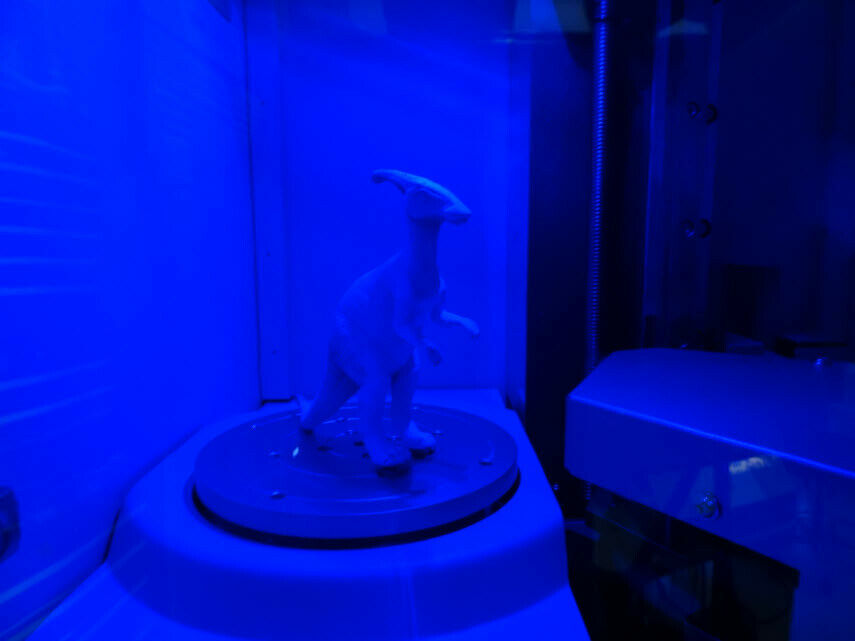

The LPX-1200 is a fully automated 3d scanner. You put the item you want to scan in the scanner and close the door. When you press the power button the LPX-1200 goes through an automatic calibration sequence. After it is done it is ready to scan, nothing else required. The LPX-1200 is the highest resolution 3d scanner that Roland

manufacturers

. When you compare it to other laser scanners the quality of scan is typically as good as or better then 3d scanners that are 3 times its price. The reason it has such a high quality scan is because the movement system Roland built for the scanning head and the over all bulk of the frame of the scanner. The drive system uses a ball screw and linear rail. The bulk mentioned is the frame that is like frames on there CNC machines which require high strength and no flexing while milling. Its hard to see from the pictures (I added one to try to point out the quality of the frame.

This scanner although it is small it weighs 77lbs.

This frame and drive systems keeps the scanner from having any movement while 3d scanning. Because of that you get

extremely

high quality 3d scans.

How can you

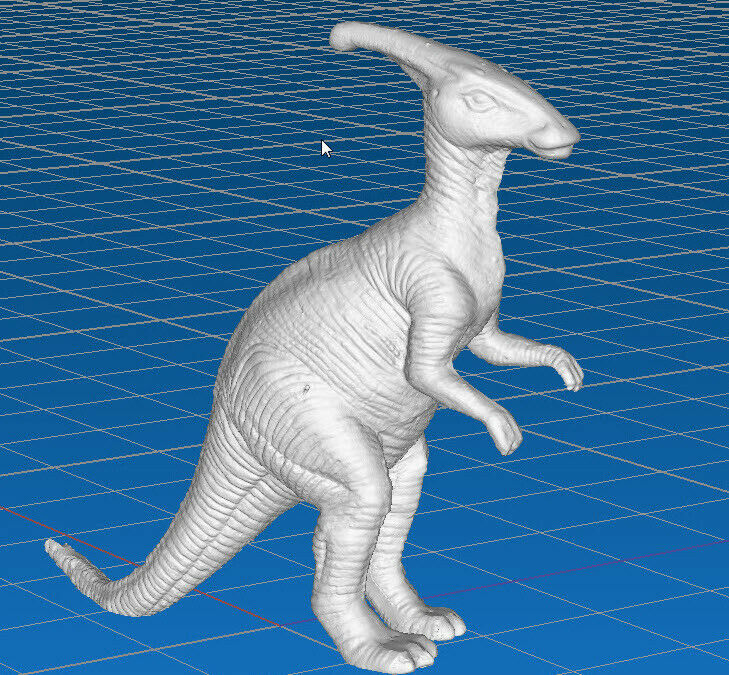

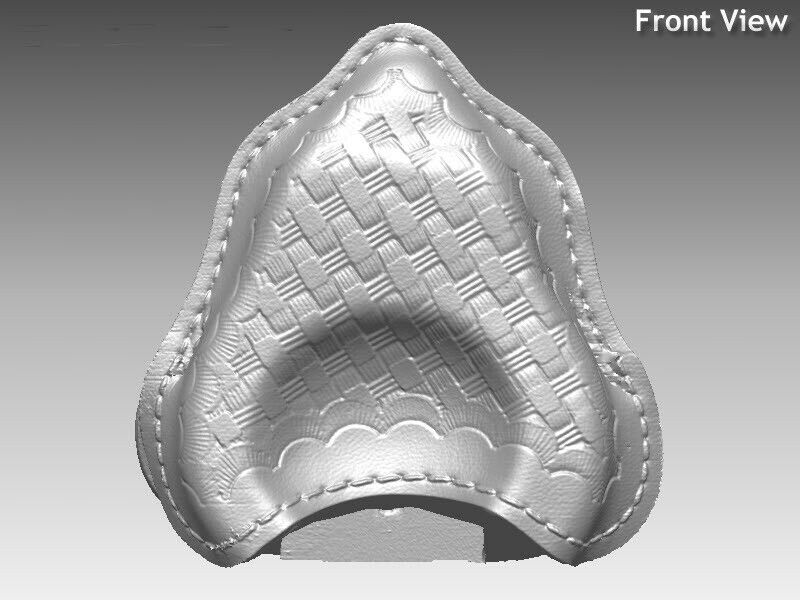

tell

the difference between a quality 3d scan and a poor 3d scan. Look for the orange peel effect on the 3d scan surface in the model. That orange peel effect is caused by noise while 3d

scanning

.

Companies

that

make cheap 3d

scanners

try to remove that noise using software and it works to some degree. But anytime you remove scan data you also lose

tolerances

. When you look at the pictures in gallery look at the high quality

surface

finish of those scans. In the leather you can see stretch marks where the leather was formed. Look at all the texture detail that was

picked

up on the toy dinosaur. This

is

the kind of things

that

makes this 3d

scanner

different then cheap 3d scanners.

The LPX-1200 is fully automated and what they mean by that is that after you set the settings in the software you press scan and walk away. You do not hold the scanner in your hand and take scans over and over again, check software go back and scan again check software ect.... The best way to really explain this is it does the same thing as a handheld scanner but is more like a 3d scanning robot. The scanning head moves up and down and the plate rotates the item being scanned. So it is fully automated.

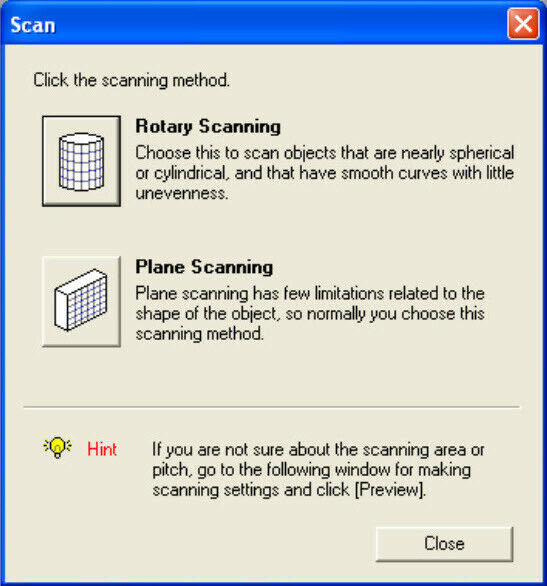

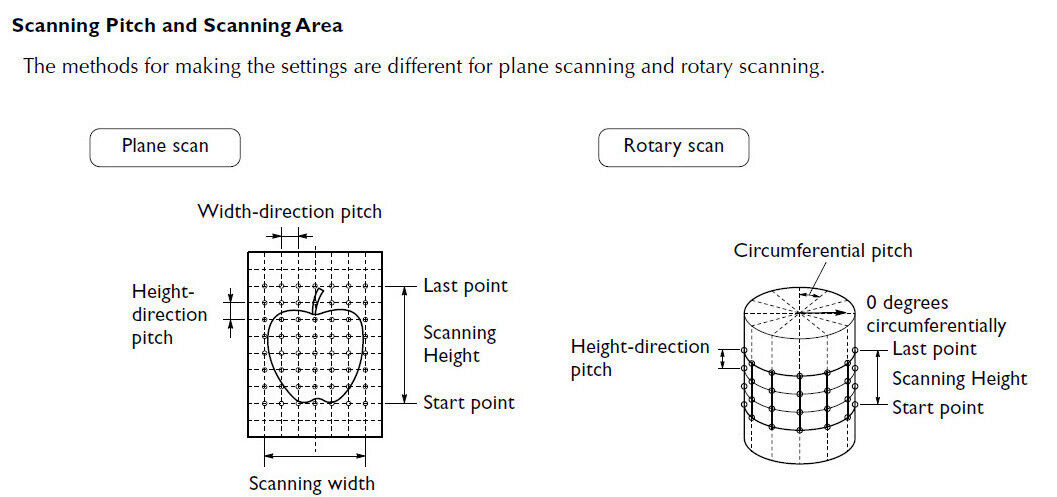

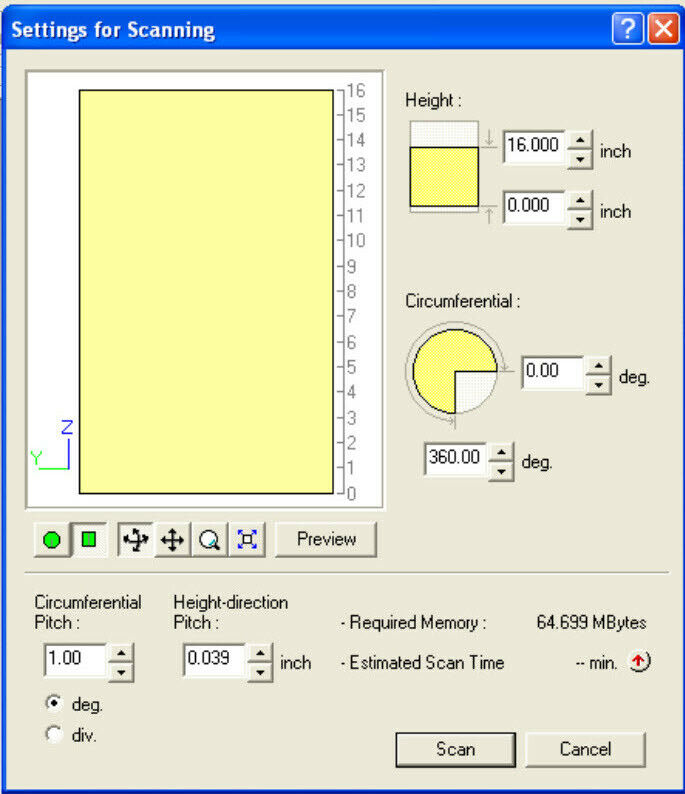

In Roland's Dr Picza 3 scanning software - you have 2 modes of operation for the automation/scanning. You can tell it do do a rotary scan which is good for a bottle or cylindrical type objects. In this case it scans the item while it rotates. It does this really fast and scans the items from top to bottom. The second type of scanning is better for square or non cylindrical objects. It is called plane scanning. The way it works is it scans the object from top to bottom then rotates a set angle like 90 degrees then scans another plane top to bottom and then rotates again. The user can tell it to add more planes to scan at any angle. For example if there is some detail you want to scan on an angle that is between 2 planes like holes at a 45 degree angle.

Once you have finished scanning you can review the 3d scan and then rescan any areas at a high resolution to pickup more detail or add additional planes if required. Once you have scanned a few objects you get the hang of how to set it up and then you can usually scan an object by setting the parameters walking off and coming back to a finished scan.

The automation is what makes this scanner so attractive. Imagine having 50 items to scan a month and having to set there and hold the scanner in your hand go up and down the whole time.

After you have finished 3d scanning you bring the scan into the Pixform Pro software to finish preparing the 3d scan file. This software will allow you to fill any holes that were left un-scanned, smooth any surfaces if you want to remove textures or for examples scratches to a surface. Once the mesh model is complete it can be used in cad software for designing an item to match or fit next to it. You can be 3d print it. The mesh model can be scaled to a larger or smaller size and then 3d printed. It can be measured for volume or size for inspection. You can modify it to make it an original piece of work.

If you need to have the model as a parametric model that is where the Pixform Pro reverse engineering software comes into play. You can open up the reverse engineering workbench in the software and create a true solid model from the 3d scan. Then other CAD programs like Solidworks will recognize the solid model and features. Pixform Pro is an OEM version of Rapidform/Geomagic.

This is a professional 3d scanner and would be used by companies who need to create 3d objects

that

have complex features that you can not measure

with

a pair of calipers.

FAQ's

Can I take a larger items and cut it up and scan it? Will

software

put it

back

together

?

Yes you can cut up an object and scan each piece

individually

and the software will realign them.

Can I scan an item like a horse toy and then make it smaller to

make

a piece

of

jewelry

circumventing the problem of

designing

a horse in 3d cad software?

Yes this is a great use for

the

scanner. 3D scan objects

that

would

be

hard to 3d model and then scale them smaller for a different

purpose

.

Scan

of toy horse is made into a small charm for necklace.

Can our students 3d scan a computer mouse and then make changes and 3d

the new

design

?

Yes this is another really good use of the

scanner

to make

customized

products or 1 off products.

Can I use the scanner to 3d scan a part of a pump that has complex surfaces, once

scanned

create slices to get contours so we can bring into our cad software to make a new parametric model?

Yes you can use the software to slice a model to get contours to have the curves you need to make lofts in a 3d cad

software.

Can I scan a golf club and remove some of the features (logo) and make some changes to face angle?

Yes you can remove things like logos from the file and make changes to the design.

Can I 3d scan a small mold that is

damaged

fix the area and then use it to cnc new mold?

Yes this is another great application take a part that is damaged 3d scan it and remove the damaged area and either 3d

it or CNC a new one.

If you

have

more

questions please message us

CUSTOMERS WHO USE THIS SCANNER ARE....

Medical

Companies (Implants, surgical guides, ect)

Custom Jewelry

Manufactures

Packaging D

esigners - Make clam shells

Toy D

esigners

Film and Props

Point of Purchase Designers - Make Dummy Products

Reverse Engineering Competitors Products

Clay Artists - 3D Scan Clay Models

Mold Makers - 3D Scan Molds

Fishing Tackle

Golf Clubs Manufacturers

Product Designers (Lots of brand name companies)

Hearing

aides /

Inner ear head phone (Scan canal mold make perfect fit)

Dental Models

Manufactures Information

The Roland LPX-1200 3D laser scanner and Pixform Pro model editing software provide a complete reverse modeling solution with superior scan quality and ease of use. This hardware/software combination is ideal for all popular CAD, CAM and animation applications. You can scan a mobile phone to design blister packaging and/or accessories, scan a hand-sculpted alien for feature animation or scan an ear canal mold for custom hearing aid manufacturing.

The included editing software offers extended functionality and compatible with popular reverse modeling software and 3D CAD export formats, while supporting robust polygon to NURB surface conversion. Featuring powerful, new NURB surface editing tools allow sub-surface patch creation and editing.

Features

0.0039" (0.1mm) scanning resolution

Captures objects up to 5" in diameter and 8"

Fast and accurate non-contact laser sensor

Combines rotary and plane scanning modes for optimum performance including the ability to capture undercuts

Included editing software offers extended functionality

Easy Operation with Dr. PICZA3 operating software and USB connection

Compatible with popular reverse modeling software and 3D CAD export formats

Supports robust polygon to NURB surface conversion

Powerful, new NURB surface editing tools allow sub-surface patch creation and editing

One button operation

Attractive, compact design for office environment

Highest Resolution Fully Automated 3D Laser Scanner

Superior Scans

The LPX-1200 uses an advanced non-contact laser sensor to quickly scan 3D objects with a 0.0039 inch scanning resolution or bigger. The combination of precision optics and motion control with a rigid cast aluminum frame produces high quality scans with minimal surface noise. While

using both rotary and plane scanning modes for optimum performance including the ability to capture undercuts.

Non-Contact Advantage

Scanned objects remain in pristine condition, thanks to the LPX-1200's non-contact laser scanning technology. Scanning restrictions are limited only to the technology itself. Glossy, clear and dark-colored objects will not scan effectively unless painted red, white or yellow in order to be "read" by the laser.

Model Editing Software

Bundled with the LPX-1200, Pixform Pro reverse modeling software is compatible with all popular CAD/CAM programs. Pixform Pro can align, merge, fill holes, decimate, remesh, and translate polygon surfaces into NURB surfaces. It supports a wide array of data output formats including DXF, STL, WRL, 3DM and IGES. IGES is the NURBs file format used by popular CAD/CAM software such as SolidWorks, Pro/ENGINEER, Inventor, Fusion 360, Mastercam, Delcam, FreeForm and Rhino.

Pixform Pro Features

Increase workflow with more efficient 3D model editing. Users can merge scans for increased quality, change the shape around curved surfaces, sharpen edges, extend shapes, add thickness and perform Boolean operations on polygon surfaces.

Dual Scan Modes

Rotary and Plane Scanning Modes offer the versatility to scan an expansive array of objects. In rotary mode, the LPX-1200 quickly scans an entire object on its fully integrated rotating table. In plane scanning mode, it scans as many as six different planes to capture side cuts and cavities.

Easy to Use

Simple to set up and use with a USB connection and one-button operation. Bundled Dr. PICZA3 operating software provides new point, line and curve scanning functions for automated surface lofting.

TECHNICAL SPECIFICATIONS

Scanning pitch

Plane scanning pitch: width direction 0.1 to 130 mm, height direction 0.1 to 203.2 mm

Rotary scanning pitch: circumference 0.18 to 3.6 degrees, height direction 0.1 to 203.2 mm

Repeat accuracy:

±0.05mm (This figure reflects standard scanning conditions established by Roland DG.)

Maximum table load weight:

11 lbs. (5 kg)

Laser

:

Wavelength: 645 to 660 nm,

Noncontact laser sensor

USB interface

Dimensions:

17-7/16 [W] x 15- 9/16 [D] x 24 [H] in.

Weight:

77.16 lbs. (35 kg)

Includes

PixForm Pro and

Dr. Picza 3

Software, 4th Axis For Fully Automated 3D Scanning, includes everything from the factory. (Software latest updates)

AC adapter, power cord, CD-ROM, clay, user's manual

Similar Products

Roland LPX-600, Roland LPX-60, Artec, Creaform, EinScan, Peel 3d, Shining 3d, Metron, Capture 3D, Faro, HP, Lecia, Afina, 3d printers, Thor3d, Next Engine, Makerbot